Table Of Content

- Results and discussion

- What are Intake Manifold Gaskets Made of?

- What are the different types of intake manifold runner designs?

- Factors Influencing Intake Manifold Design

- Spin Control: Why Alternator Pulley Ratio Is Important

- The Latest Trends in Custom Billet & Sheetmetal Intake Manifolds

- Does the intake manifold gasket need sealant?

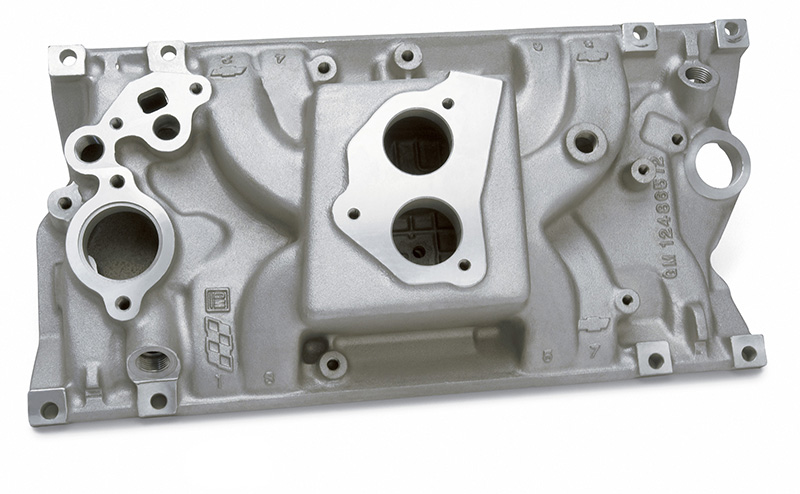

One common material used in the construction of intake manifolds is plastic. This may seem surprising, considering the high temperatures and pressures involved in the intake system. However, there are several reasons why plastic is chosen as the material for intake manifolds.

Results and discussion

The lifespan of an intake manifold can vary depending on various factors such as the quality of the material, maintenance, and driving conditions. Generally, a well-maintained intake manifold can last for the lifetime of the vehicle. The intake manifold runner control is typically located on the intake manifold itself.

What are Intake Manifold Gaskets Made of?

This can enhance the overall driving experience for enthusiasts who enjoy a more pronounced engine sound. The intake manifold pressure sensor, also known as the MAP (Manifold Absolute Pressure) sensor, measures the pressure inside the intake manifold. This information is crucial for the engine control unit (ECU) to calculate the correct air-fuel mixture and adjust engine performance accordingly. The ultimate is to design a manifold with no constraints on shape, you can cut it out of billet. Giving the engine builder complete control of the air entering the plenum and intake runners.

What are the different types of intake manifold runner designs?

However, the qualitative analysis by observing structure of intake flow in the manifold can be done. Moreover, more detailed analysis can be performed with additional simulation. In addition to intake manifold design software and Solidworks, there are other tools and techniques that designers use to optimize intake manifold design. These include selecting the right intake manifold material, considering the shape and length of the intake runners, and implementing intake manifold tuning techniques. Turbochargers are another form of forced induction that utilizes exhaust gases to drive a turbine, which in turn compresses the intake air.

Factors Influencing Intake Manifold Design

Here, I am being assisted, as is so often the case, by crew chief/racer Mervyn Bonnet. Our tests clearly show that an efficient two-plane intake typically responds to carb CFM numbers better than its single-plane race counterpart, which runs counter to popular belief. This RPM Performer Air Gap features runners separated from the lifter valley to cut heat transfer to runners. Holley, Dart, and Professional Products also produce similarly effective two-plane intakes.

Spin Control: Why Alternator Pulley Ratio Is Important

The design of the intake manifold directly affects the engine’s power output, fuel efficiency, and overall performance. In this article, we will explore the theory behind intake manifold design, the factors influencing its design, and the calculation involved in designing an efficient intake manifold. For instance, let’s consider an example where we want to design an intake manifold for a high-performance engine. By using intake manifold design software, we can input the desired specifications such as runner length, diameter, and shape. The software will then simulate the air flow and provide us with data on the intake manifold’s performance, including factors like air velocity, pressure drop, and volumetric efficiency.

The intensified in-cylinder flow during intake process by the flow supplied by intake port is weakened during the compression process. Through the compression process the flow momentum loss occurred by friction. Additionally, there was flow momentum transition to the turbulent kinetic energy.

Ford Racing Three Valve Intake Manifold Testing - MotorTrend

Ford Racing Three Valve Intake Manifold Testing.

Posted: Sat, 17 Jul 2021 00:01:54 GMT [source]

This high pressure and high heat only have one thing in mind, to beat relentlessly on the first thing to get in the way – the pistons. This Chevrolet LS6 engine tops the 750-hp mark at 7,400 rpm and features an 11- inch runner. The volume averaged velocity was calculated, and each cell volume in spark plug gap was considered. For the turbulent kinetic energy of the region, the mass averaged turbulent kinetic energy was used. Turbulent kinetic energy was computed based on the fluctuation component of the turbulent vector field. The turbulent vector field was calculated by subtracting the mean flow vector field in the flow vector field of each cycle.

Additionally, changes in the intake manifold radius were considered to enhance the in-cylinder flow for straight intake manifold. The Mie-scattering was conducted using a metal-halide lamp as a light source and BnB-1 middle fog as a flow tracer. Three conditions were used with varying intake throttle valve opening angles. The image of the distribution of fog in the steady-state experiment demonstrated the stream-lines of the flow from intake manifold inlet to the cylinder.

It’s important to research and consult with experts or manufacturers to ensure compatibility and optimal performance when selecting an intake manifold for your specific car model. Cleaning the intake manifold not only improves engine performance but also helps prevent potential issues such as intake manifold leaks and damage to other engine components. For example, the MAP sensor helps the ECU determine the engine load, altitude, and throttle position. Based on this data, the ECU can adjust the ignition timing, fuel injection, and other parameters to optimize engine performance and fuel efficiency. Intake manifold gaskets should be replaced if they are damaged, leaking, or causing vacuum leaks. Signs of a faulty gasket include rough idling, decreased engine performance, and coolant or oil leaks around the intake manifold.

By incorporating tuning mechanisms such as variable length intake runners or intake manifold resonance, engineers can optimize the intake system’s performance at different engine speeds. This tuning allows for better torque delivery across a wide range of engine speeds, enhancing overall drivability and performance. By understanding the function and role of the intake manifold in an engine, you can appreciate its importance in optimizing the combustion process and maximizing the engine’s performance. Whether it’s a gasoline or diesel engine, the intake manifold plays a crucial role in ensuring efficient and powerful operation.

The simulation model was validated based on the PIV experiment in the cylinder and Mie-scattering experiment of intake manifold, and its results agreed well with the experiment results. And the straight manifold had an effect of the strengthening the in-cylinder flow, so that the turbulent kinetic energy near TDC was increased to maximum 11% than curved manifold. Especially at 2000 rpm, the tumble ratio increased 55% at intake manifold radius of 10 cm than of 7 cm at bTDC 280 deg. Therefore, for the purpose of enhancing the in-cylinder flow near spark plug timing, shortened distance between intake manifold inlet and port and increasing the manifold radius is required. Intake Manifold Geometry Design plays a crucial role in the performance of an internal combustion engine.

Greddy RX35 Intake Manifold/ Billet Throttle Bodies - MotorTrend

Greddy RX35 Intake Manifold/ Billet Throttle Bodies.

Posted: Wed, 07 Jul 2021 01:51:49 GMT [source]

These runners feed from a suitably sized plenum so that, at WOT, the plenum appears (to each intake runner) to be open air that has been pre-mixed with fuel. This being the case, time should be taken to do a reasonably-well-executed port matching job, as a minimum. The example shown here has been fully ported, and a thermal barrier was applied to the inside. On the outside, a powder-coated finish has sufficient shine, even in red, to help reflect heat—but a better solution here is a chromate ceramic finish. The water jacket also has an insulating finish applied to its internal walls to cut heat conducted from the water to the runners.

Intake manifold design optimization can enhance engine performance by maximizing air flow, improving intake air temperature, and increasing manifold pressure. This software allows users to input various parameters such as intake runner length, diameter, shape, taper, and resonance control. It then uses computational fluid dynamics (CFD) algorithms to simulate the air flow through the intake manifold and provides valuable insights into the performance characteristics. Intake manifold design software is a powerful tool that allows engineers to create and analyze intake manifold designs in a virtual environment. This software provides a range of features and functionalities that assist in the design process.

When the piston accelerates downwards, the pressure at the output of the intake runner is reduced. This low pressure pulse runs to the input end, where it is converted into an over-pressure pulse. Porting and polishing an intake manifold is a popular technique used to improve airflow and increase performance. This process involves removing any rough edges, imperfections, and restrictions within the intake manifold’s passages.

In layman’s terms, if you can’t reach the area with your finger it’s going to difficult to machine,” Steve Morris shared with us. Racing design and feedback has been combined, along with Solid Works Computational Fluid Dynamics Software to produce this intake from Plazmaman. Tunnel ram installations intended to use carburetors and a pair of 4-barrel injector throttle bodies can be used to equally good effect. From this, we subtract half the inlet diameter, which is is 2.25 inches in our example.